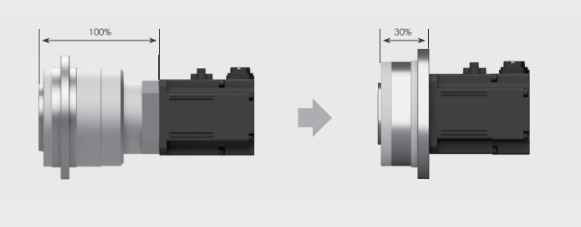

From 1st stage up to 100:1

‘Powerful torque’ realized through reduction ratio

In automated production lines, agricultural and construction machinery, conveyor belts,

process equipment and other high-load applications, the torque output of the reducer is critical.

The high reduction ratio of BSR series reducers significantly reduces input speed, increasing output torque.

This makes it an excellent choice for moving heavy or resistant objects.

Increases work efficiency and ensures stable operation in high-load environments.